Smart stock replenishment becomes essential as companies approach the final stretch of the year. Seasonal spikes, accelerated demand cycles, and tighter logistics windows make inventory decisions more critical than at any other moment in the business calendar. When organizations fail to anticipate these fluctuations, shortages emerge quickly, affecting customer satisfaction and revenue stability. A streamlined and data-informed approach minimizes these risks and maintains operational balance during the most demanding period.

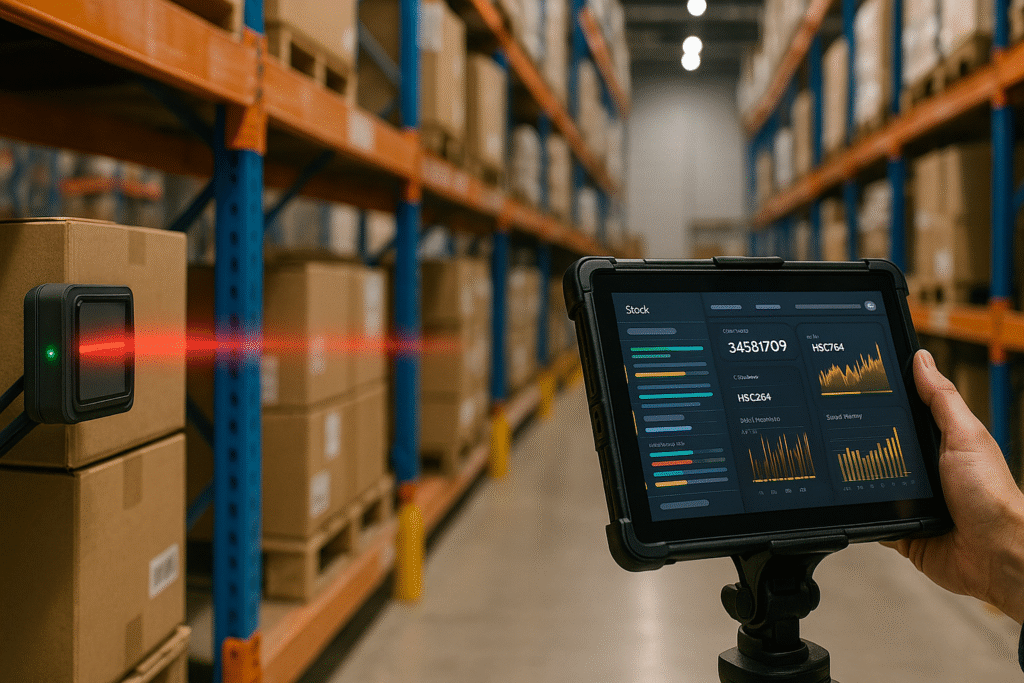

Enhancing visibility through real-time inventory monitoring

Year-end supply challenges often stem from poor visibility across warehouses, suppliers, and fulfillment centers. Real-time monitoring provides a clear and continuous understanding of stock movements, enabling teams to detect anomalies before they escalate. Integrating automated alerts, API-based supplier updates, and item-level tracking allows businesses to react faster when demand surges unexpectedly. This level of transparency supports more accurate replenishment cycles and ensures that high-priority items never fall below safety thresholds during peak activity.

Using predictive analytics to refine demand forecasting

Demand forecasting becomes significantly more complex at the end of the year due to holiday promotions, shifting consumer behaviors, and constrained transportation networks. Predictive analytics help organizations analyze historical patterns, promotional calendars, and external variables such as market trends or regional events. By relying on machine learning models instead of manual estimates, companies can align purchasing decisions with realistic demand expectations. This approach reduces excess inventory while preventing the stockouts that typically occur when teams underestimate year-end acceleration.

Strengthening supplier coordination for faster replenishment cycles

Supplier performance plays a decisive role in preventing shortages. Strong coordination ensures that replenishment timelines remain reliable even when lead times fluctuate. Establishing shared dashboards, implementing minimum stock agreements, and negotiating flexible order quantities enhance resilience. Organizations that communicate forecasts early and maintain consistent dialogue with suppliers achieve smoother replenishment cycles and faster recovery from unexpected spikes. This collaboration is especially important when global logistics slow down during the holiday period.

Optimizing warehouse operations with automated workflows

Automation supports faster and more accurate replenishment by reducing manual bottlenecks inside the warehouse. Automated picking routes, system-driven reorder triggers, and dynamic slotting contribute to better resource allocation and higher operational precision. These improvements accelerate the movement of products through receiving, storage, and dispatching stages. As a result, teams can fulfill orders efficiently even when volume increases sharply at the end of the year, reducing the likelihood of shortages caused by internal delays.

Source: McKinsey & Company