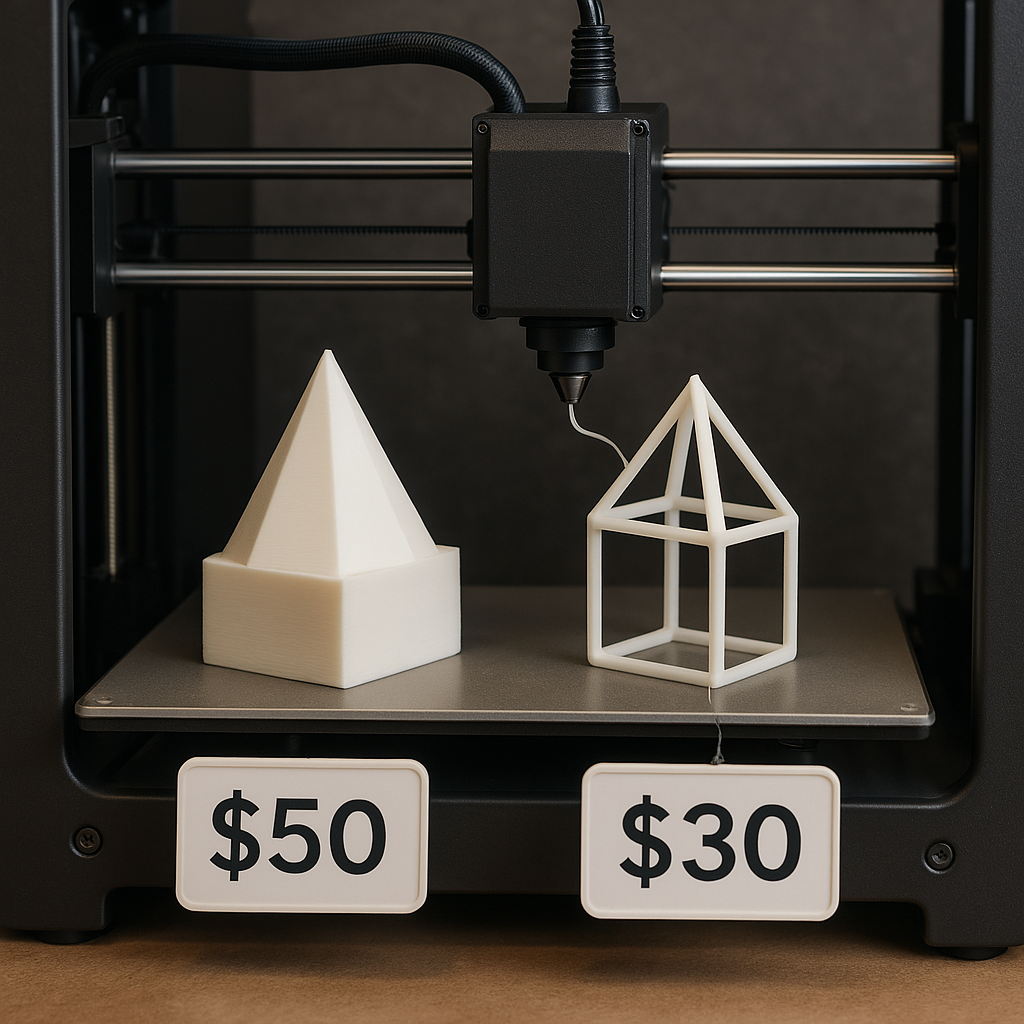

If you’re looking to reduce 3D printing cost, the best strategy is to optimize each phase of the process: design, production, and finishing. Small changes can lead to significant savings in materials, machine time, and post-processing.

Design Smart to Save

Begin with hollowing your model. Removing unnecessary internal material can greatly reduce material use and print time. This approach works especially well with SLS and MJF technologies. If your model is just a prototype or visual piece, consider scaling it down—smaller prints cost less due to reduced volume.

Even basic design adjustments can help. Avoid sharp corners, unsupported tall walls, and extreme overhangs. These require extra supports or reprints, increasing costs. Try incorporating cutouts or reducing wall thickness in non-critical areas to lower material consumption.

Choose Affordable Materials and Processes

Not every part needs high-performance materials. PLA or PA are ideal for basic prototypes and visual models. Reserve expensive options like ULTEM or DLS resins for parts that demand it. Similarly, FDM and MJF are cost-effective processes suitable for most use cases.

Match the printing method to your project’s goals. If you don’t need ultra-fine detail or extreme durability, choose the more affordable technology.

Minimize Finishing Expenses

Post-processing can quickly inflate your budget. SLS and MJF prints don’t need support structures, which means less cleanup and lower labor costs. For color, dyeing is faster and cheaper than painting, though not as long-lasting. Vapor smoothing looks great but adds cost—use it only when appearance is crucial.

By making thoughtful choices from start to finish, you can effectively reduce 3D printing cost and increase the efficiency of your projects.

Source: xometry