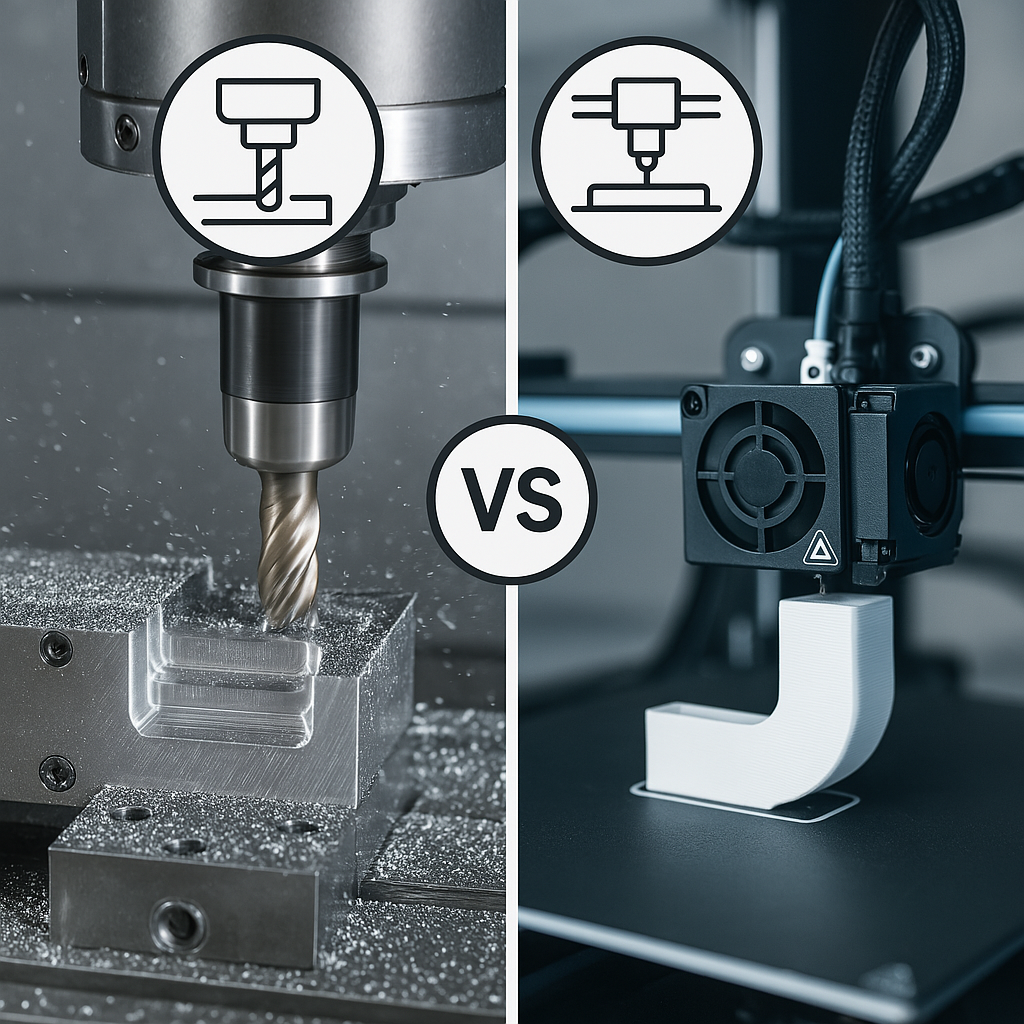

When comparing CNC vs 3D printing, the right choice depends on your part’s purpose, material, and complexity. Both are powerful tools for manufacturing, but each excels in different situations.

CNC Machining: Precision and Strength

CNC machining removes material from a solid block using cutting tools. It delivers excellent surface quality and tight tolerances, especially for metals like aluminum or steel. CNC is ideal for mechanical parts that need high strength, durability, or heat resistance. It’s also more consistent for medium to large production runs.

3D Printing: Flexibility and Speed

3D printing builds objects layer by layer, allowing for complex geometries that would be difficult or expensive to machine. It’s faster and cheaper for prototyping or small batch production, particularly when intricate shapes or internal channels are involved. While plastics are most common, some metal printing is also available.

Material and Cost Considerations

CNC offers more materials and better dimensional accuracy, but setup and tooling costs can be high. 3D printing reduces waste and upfront costs, but may require post-processing and has lower tolerance limits.

When to Use Each

Choose CNC if you need functional, high-strength parts or are producing higher volumes. Opt for 3D printing for faster prototypes, lightweight designs, or when cost is a constraint.

Knowing the strengths of CNC vs 3D printing lets you choose smarter for each project—whether you’re testing an idea or scaling production.

Source: xometry