The benefits of 3D printing in manufacturing are transforming how companies design, produce, and scale their products. One of the most recognized advantages is cost reduction. Because 3D printing uses minimal raw materials and requires less manual labor, it significantly lowers operational costs compared to traditional manufacturing methods.

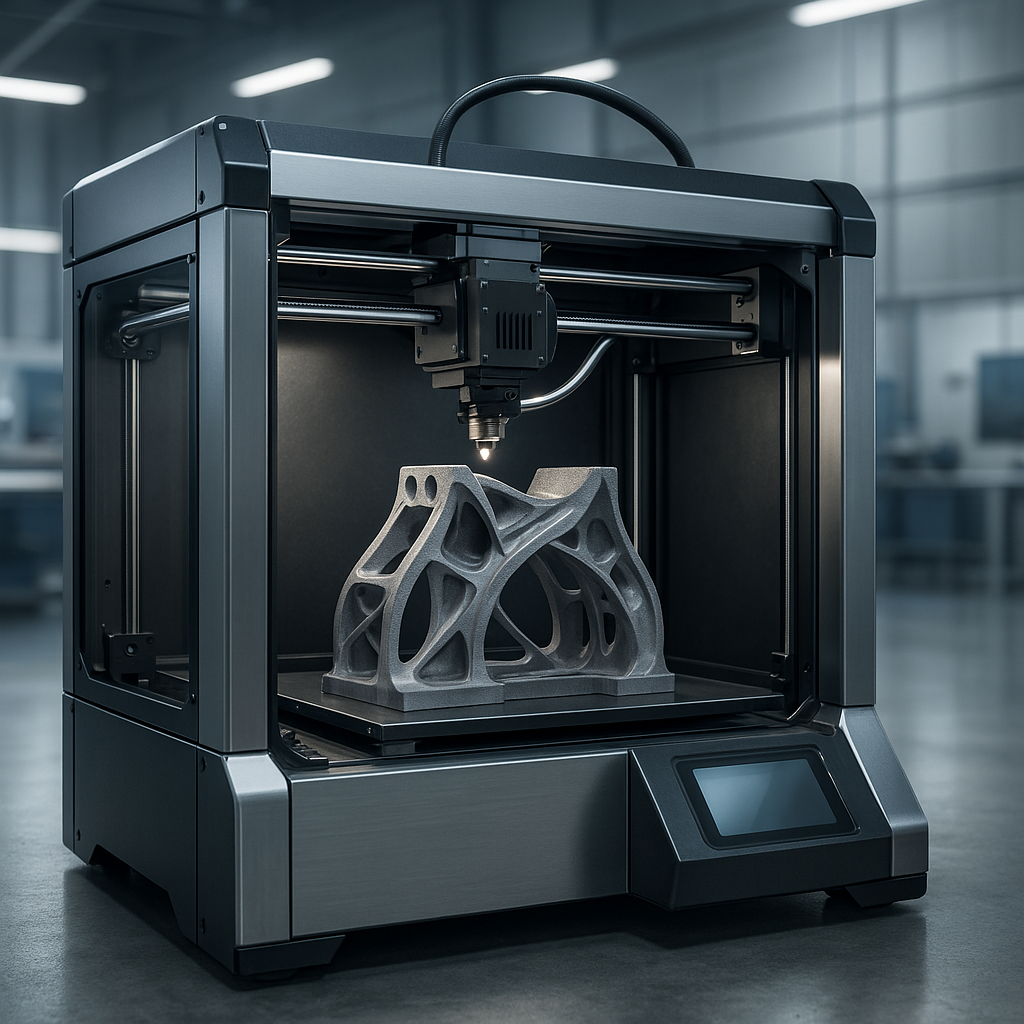

Another key benefit of 3D printing in manufacturing is its ability to produce complex designs. Traditional techniques often have design limitations, especially when it comes to internal structures or intricate geometries. In contrast, 3D printing enables manufacturers to create detailed shapes, such as directional holes or square interior cavities, with fewer constraints.

Waste reduction is another major benefit of 3D printing in manufacturing. Additive manufacturing uses only the exact amount of material needed, minimizing excess and reducing the environmental impact. This efficiency is both sustainable and cost-effective.

In-house prototyping is also among the major benefits of 3D printing in manufacturing. Instead of outsourcing prototypes and waiting days or weeks, companies can print functional models on demand. This accelerates product development and allows for faster iterations.

Finally, one of the emerging benefits of 3D printing in manufacturing is its potential to create local economic opportunities. Because it’s more affordable and less labor-intensive, businesses can operate domestically without relying on overseas production. This opens up jobs and growth in economically depleted areas.

Source: sharrettsplating