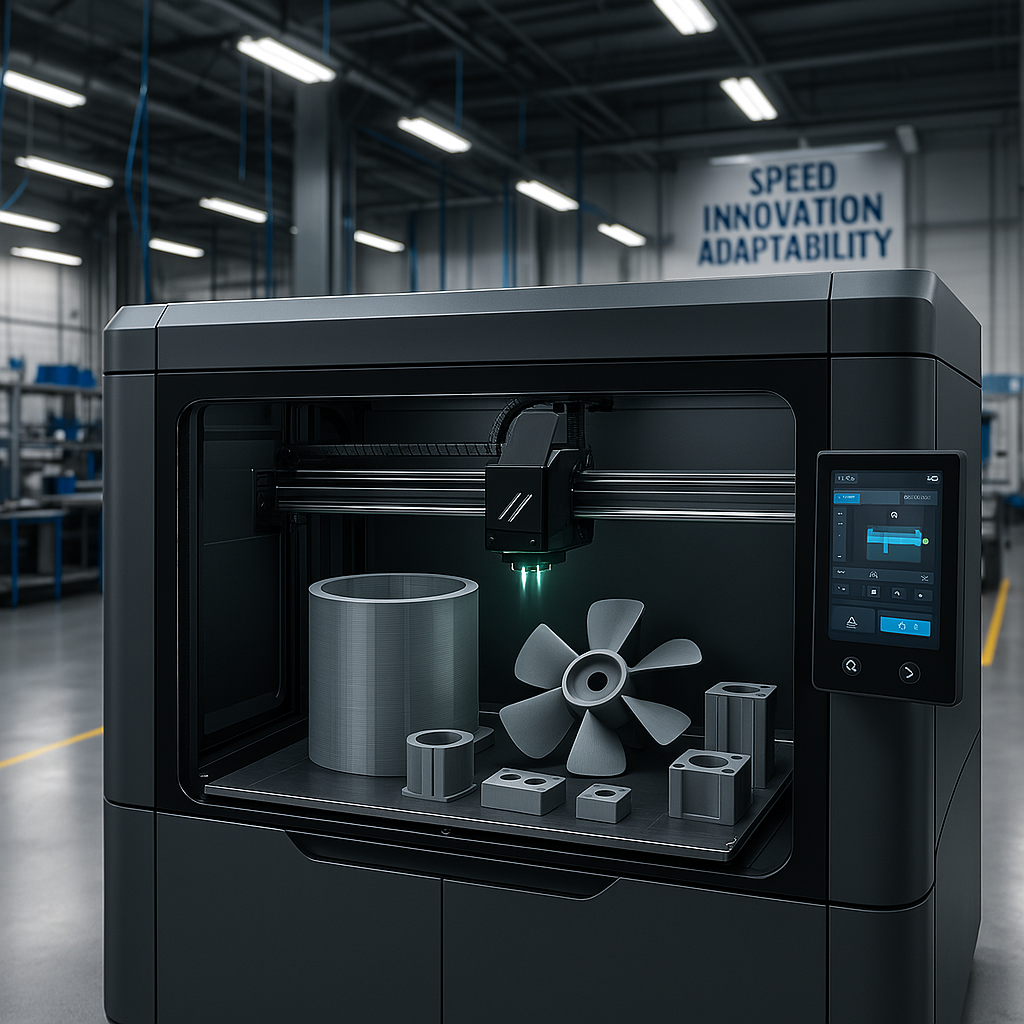

Understanding how 3D printing is used in manufacturing reveals just how flexible and valuable this technology has become. One of the most important applications is for product enhancements. Traditional manufacturing can take weeks to implement a small change. With 3D printing, a design can be modified digitally and printed almost immediately, allowing companies to enhance and release updated products much faster.

Another common way 3D printing is used in manufacturing is for low-volume production. When testing new products or parts, manufacturers often rely on small production runs. 3D printing makes this process faster and more affordable, allowing businesses to test designs and market response without investing in expensive molds or tooling. This flexibility is key for innovation and agile product development.

Additionally, 3D printing is increasingly supporting high-volume production. While it was once seen only as a prototyping tool, today’s advanced 3D printers can operate continuously and at scale. Manufacturers can integrate 3D printing into production lines to reduce delays, improve product quality, and adapt more quickly to changes. This is especially helpful for products in high demand, where efficiency and adaptability are critical.

The speed and adaptability of 3D printing also mean that companies can react quickly when they need to adjust machinery, shift designs, or scale production. Compared to older, slower manufacturing processes, 3D printing helps minimize downtime and maximize productivity.

Source: sharrettsplating