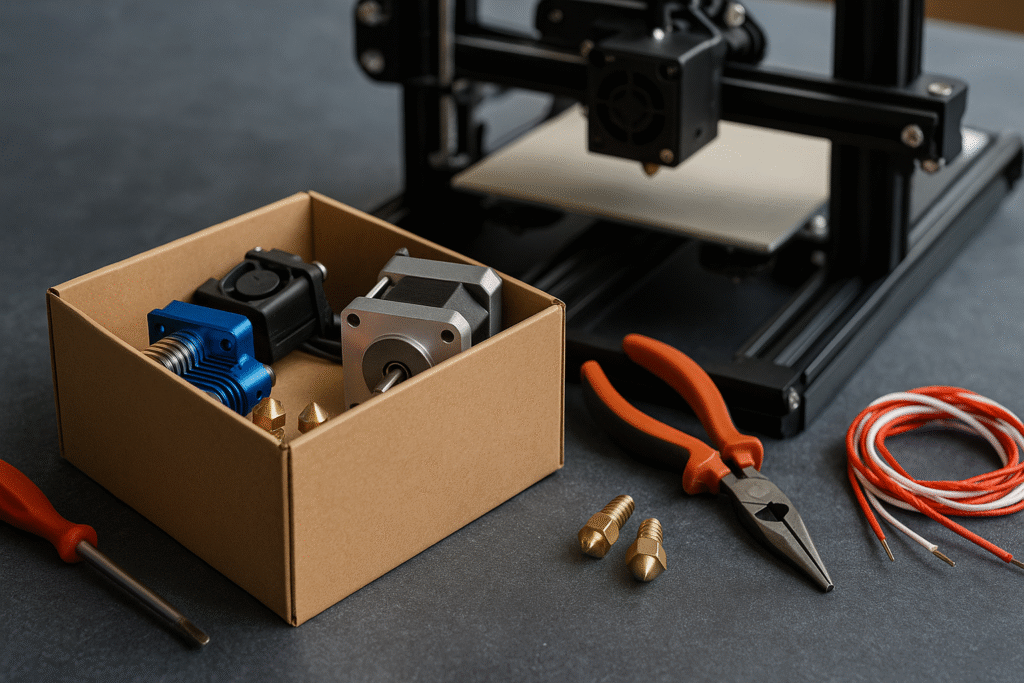

3D printer spare parts import is a critical element in ensuring consistent performance and uptime in industrial environments. As additive manufacturing becomes more integrated into production, the need for immediate access to replacement parts increases. Components like extruders, nozzles, thermistors, and motion systems are subject to wear and failure under high-volume use. Without a streamlined supply of spares, operations risk delays and higher maintenance costs.

Establishing a reliable spare parts strategy allows manufacturers to maintain system functionality and meet production schedules. In many cases, local inventories may not cover all needed parts, or delivery timelines may be incompatible with production demands. Importing spare parts becomes essential to reduce downtime and avoid dependency on limited regional supply chains.

3D Printer Spare Parts Import and Supply Chain Continuity

The role of 3D printer spare parts import is central to building a resilient and responsive supply chain. By accessing global sources, businesses can maintain better stock rotation, acquire certified components, and secure parts that are no longer supported locally. Importing also supports lean inventory practices by enabling just-in-time procurement of non-critical items, helping reduce costs tied to excess storage.

Spare part import strategies also allow for access to specialized components that may only be produced in certain regions. This flexibility enhances maintenance planning and improves the ability to scale operations without compromising equipment availability.

Managing Quality and Logistics in Import Operations

Spare parts logistics require precision. Components must be protected during transit through reinforced packaging and climate-controlled shipping, especially in the case of electronics. Delays at customs can be avoided through proper documentation, including accurate HS codes and clear declarations. To ensure part quality, buyers should establish criteria for supplier selection, including verification of materials, tolerances, and functional specifications.

A structured approach to sourcing, logistics, and quality assurance in spare parts import is key to sustaining uptime and minimizing operational risk in additive manufacturing environments.

Source: mdpi